Manufacturing

footprint strategy

Optimise your global network of factories and suppliers to reduce costs and enhance responsiveness through our established approach to manufacturing footprint strategy.

Cost reduction is often the primary motive for reconfiguring a production network, and in applying our work with leading companies we have seen significant cost reductions from restructuring sub-optimal networks that have developed more by accident than by design. In one case, the company declared $55m annual cost savings five years after publicly announcing the strategy.

But cost reduction is not everything. Accessing the most attractive markets is at least as important and there are other strategic factors to consider, such as access to key resources, innovation capability, agility and risk. As well as being clear about their own strategic objectives, firms also need to take into account external market forces and the technology discontinuities that create new product and process opportunities. This is the context against which reconfiguration should be considered.

Optimise your global network of factories and suppliers to reduce costs and enhance responsiveness through our established approach to manufacturing footprint strategy.

Cost reduction is often the primary motive for reconfiguring a production network, and in applying our work with leading companies we have seen significant cost reductions from restructuring sub-optimal networks that have developed more by accident than by design. In one case, the company declared $55m annual cost savings five years after publicly announcing the strategy.

But cost reduction is not everything. Accessing the most attractive markets is at least as important and there are other strategic factors to consider, such as access to key resources, innovation capability, agility and risk. As well as being clear about their own strategic objectives, firms also need to take into account external market forces and the technology discontinuities that create new product and process opportunities. This is the context against which reconfiguration should be considered.

HOW WE CAN HELP

IfM Engage provides a structured approach to reconfiguring global manufacturing footprints which has been used by multinationals including IKEA, Emerson, Grundfos, Electrolux.

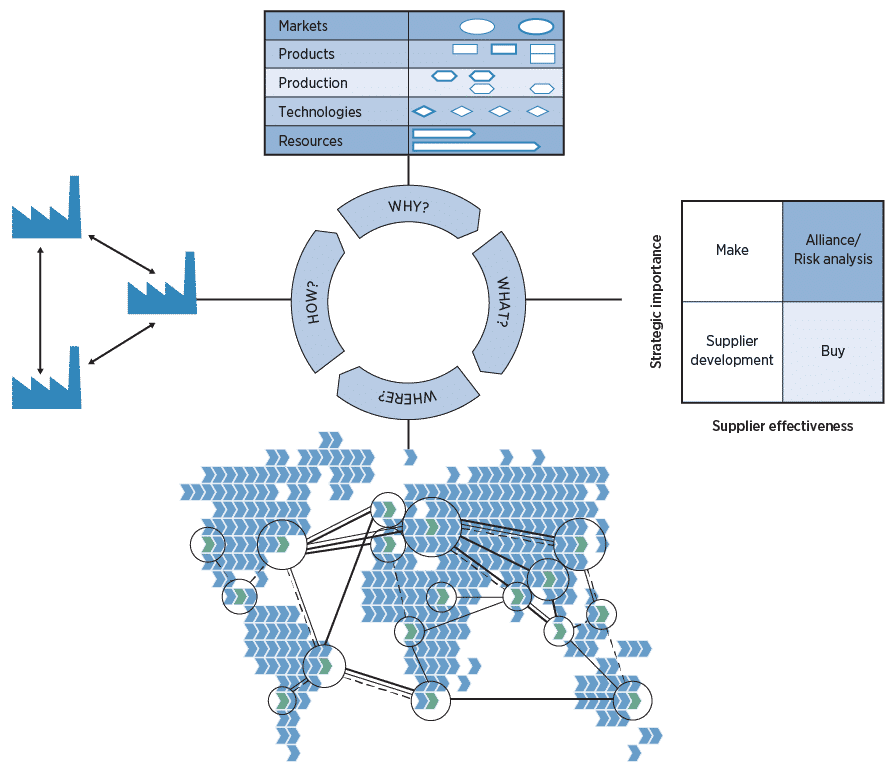

By addressing areas related to four key questions, we help organisations optimise their global production networks whilst building the capability to use the IfM’s Manufacturing Footprint approach as a key strategic planning tool for the future.

WHY?

Why reconfigure the network?

This stage involves understanding the market and technology drivers faced by the business and describing the key imperatives for changing the manufacturing footprint.

WHAT?

What to make, what to buy?

Which manufacturing processes support competitive advantage, how should we utilise strategic supply partners, what should we outsource for low cost.

WHERE?

Where should each type of plant be located?

Developing design principles, a range of possible future scenarios, and a clear recommendation for the 5-year footprint target.

HOW?

How to achieve the desired transformation

Defining the required transformation programme and developing the enabling capabilities.

FEATURED RESOURCES

FEATURED RESOURCES

Frank Wagner, former SVP of Global Manufacturing Operations, Electrolux

Frank Wagner, former SVP of Global Manufacturing Operations, Electrolux

CASE STUDIES

CASE STUDIES

ENGAGE WITH US

Digital Supply

Chains Consortium

The Digital Supply Chains Consortium is a unique collaboration between industrial member companies and the Institute for Manufacturing (IfM). It brings together some of the world’s leading organisations and academics, who are focused on delivering the tools, education and insights needed for the supply chains of the future.

Consultancy

services

Talent and capability

development

ENGAGE WITH US

Digital Supply Chains Consortium

The Digital Supply Chains Consortium is a unique collaboration between industrial member companies and the Institute for Manufacturing (IfM). It brings together some of the world’s leading organisations and academics, who are focused on delivering the tools, education and insights needed for the supply chains of the future.

Consultancy services

Our global network of manufacturing footprint strategy experts combine the latest insights with senior level industry experience. We take a collaborative approach and understand our client’s individual objectives and draw from research, world class tools and industrial knowledge to empower impactful decisions and action.

Talent and capability development

Through our open and bespoke courses, individuals and teams can advance their manufacturing footprint strategy including our making the right things in the right places course.

Thore Bänsch, Senior Director, Operations Strategy, Grundfos

Thore Bänsch, Senior Director, Operations Strategy, Grundfos

HOW THIS SOLUTION WAS DEVELOPED

The IfM’s Manufacturing Footprint Strategy approach was developed through research at the Centre for International Manufacturing (CIM), part of the Institute for Manufacturing. CIM focuses on strategic and operations management research, working closely with industrial and institutional partners.

Academic Expert: Jag Srai

FEATURED EXPERT

Kam Gossal

HOW THIS SOLUTION WAS DEVELOPED

The IfM’s Manufacturing Footprint Strategy approach was developed through research at the Centre for International Manufacturing (CIM), part of the Institute for Manufacturing. CIM focuses on strategic and operations management research, working closely with industrial and institutional partners.

Academic Expert: Jag Srai

FEATURED EXPERT

Kam Gossal

LATEST INSIGHTS

GET IN TOUCH

Contact us to find out more about how we can help you to optimise your global production networks and reduce costs through our established manufacturing footprint approach for global supply chain reconfiguration.