From Automation Ambition to Scalable Impact

WABTEC CORPORATION

Impact

A data-driven process to prioritise a pipeline of high-value automation projects, projecting over $2.5 million in initial annual returns.

Empowered strategic decision making by creating a shared language between technical teams and senior leadership, ensuring buy-in and a unified vision.

Built lasting internal automation capability through knowledge transfer, enabling the company to own and run the assessment process independently.

Impact

A data-driven process to prioritise a pipeline of high-value automation projects, projecting over $2.5 million in initial annual returns.

Empowered strategic decision making by creating a shared language between technical teams and senior leadership, ensuring buy-in and a unified vision.

Built lasting internal automation capability through knowledge transfer, enabling the company to own and run the assessment process independently.

The challenge: From Strategic Ambition to a Practical Starting Point

The ambition to embrace automation at Wabtec was clear and backed by senior leadership. An “automation council” was formed to define a corporate strategy, but they faced a critical hurdle: they had the high-level ambition but lacked a practical, structured process to identify and prioritise the right projects at the facility level. They needed a proven methodology to serve as the starting point and foundation for scaling automation.

The leadership team explored various external vendors but found most offered product-specific solutions. They needed an impartial partner who could help them build a robust and insightful approach from the ground up. The search for this led them to the Institute for Manufacturing (IfM) at the University of Cambridge and its research-backed Automation Assessment.

“Most solutions we found were product-led or focused on a single technology or solution provider wanting to sell their products. We needed an approach that was independent of an actual solution provider. That way we could focus in on the significant value in the ideas from our employees who understand the context of our organisation and facilities. The IfM’s Automation Assessment was unique in this regard and exactly what we were looking for.”

Thomas Rupp, Lead Manufacturing Engineer, Wabtec Corporation

The Approach: Strategic Pilots to Validate and Scale

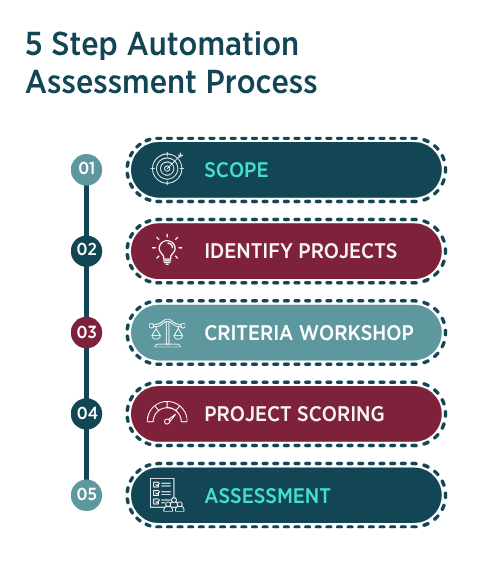

The IfM’s Automation Assessment is a structured, five-step process to guide companies from initial scoping to a prioritised implementation plan. Through a series of workshops, it is designed to be a collaborative and practical process through which experts from across an organisation identify automation opportunities and projects.

IfM Engage facilitated two initial pilot workshops with Wabtec in facilities in the United States. The engagements were intentionally framed by Wabtec not as a top-down “assessment,” but as a collaborative “workout.” This subtle shift in language was crucial, creating an empowering environment that encouraged site-level teams to actively participate in building their own automation journey. The goal was to harness the deep knowledge that already existed within the facilities and channel it into a structured, prioritised plan.

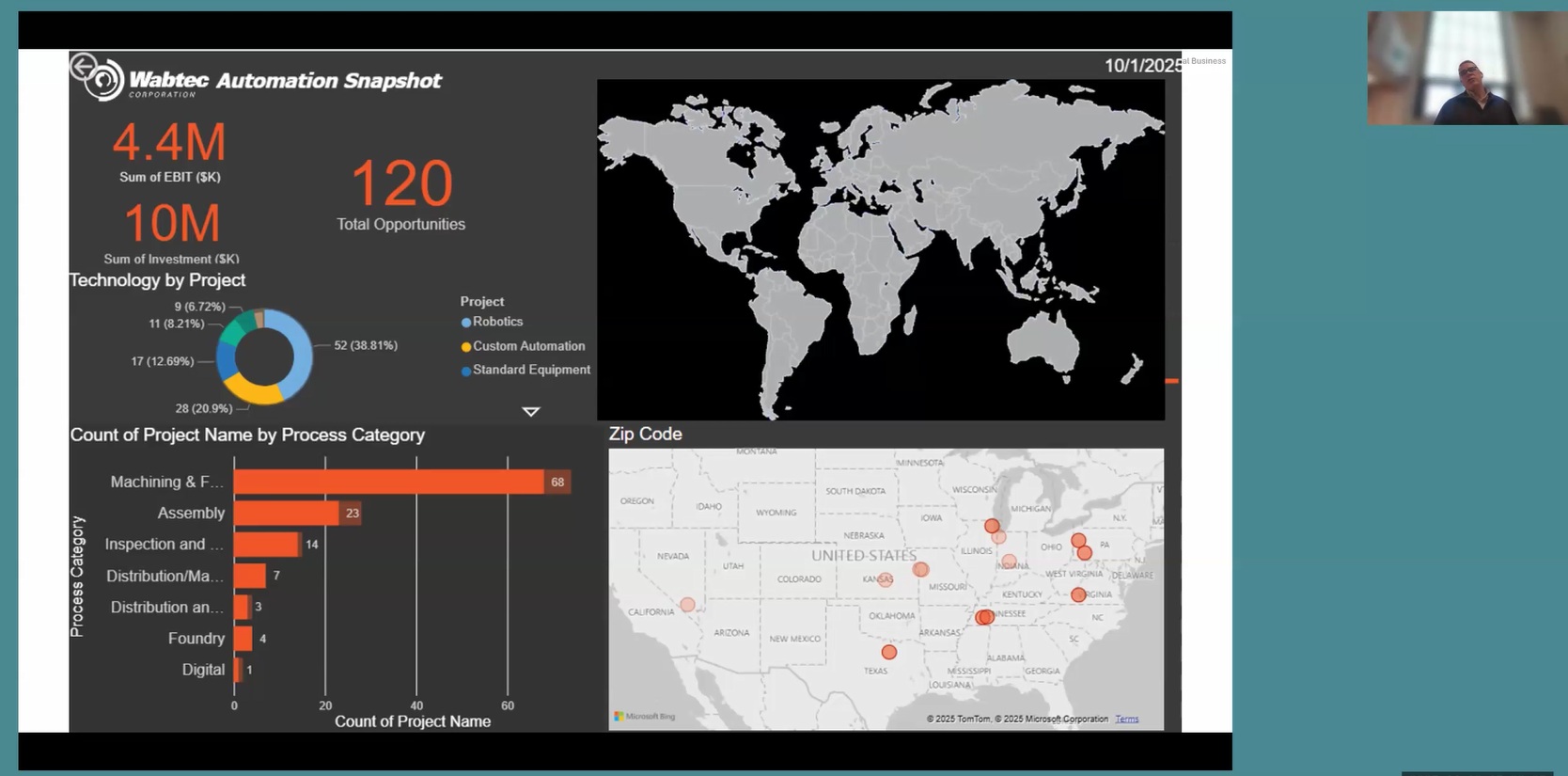

The experience was very successful, leading Wabtec to scale the initial initiative to an additional five facilities, making seven in total to date. From the seven ‘workout’ events, over 250 distinct automation opportunities have been identified.

A wide range of processes and activities across Wabtec’s operations were considered, including machine tending and deburring, inventory management, assembly, and foundry operations, empowering teams to think broadly. This resulted in ideas that ranged from the physical to the digital, including projects to exploit technologies like robotics, cobots, AGVs and palletisers, alongside data-driven solutions targeting process optimisation in inventory management and automated inspection.

The real power in the approach, however, was in providing a clear, objective method to filter this high volume of ideas. The Automation Assessment’s data-driven framework gave the teams the focus they needed, enabling them to distil a long list of possibilities into 15 key initiatives. Just as importantly, it provided clarity on the reasons behind each decision, ensuring alignment and consensus on which opportunities to move forward with.

The tool also acted as a “translator” between technical teams and senior leadership. Its simple visual output allowed leaders to see the “why” behind each priority, creating a shared language and building the confidence needed to fully invest in the long-term, scaled-up strategy. This shared language and alignment also enables local engineers to have the confidence to champion new and innovative ideas.

IfM Automation Assessment

The IfM’s Automation Assessment takes a structured approach to guide organisations through the decision-making process. The tool highlights and prioritises steps that should be taken to progress companies along the automation maturity path.

“The tool gives us a data-driven way to filter a high volume of potential projects, giving us much needed focus. It clearly shows us the key areas to pursue, but just as critically, it also highlights which projects to avoid, preventing us from investing resources in low-value initiatives.”

Thomas Rupp, Lead Manufacturing Engineer, Wabtec Corporation

Impact: Delivering Financial Returns, Building Internal Capability, and Driving Strategic Decisions

The Automation Assessment delivered significant and measurable impact across the organisation, from the factory floor to the boardroom.

- Financial Impact: The process has been transformational. The 15 major projects identified and prioritised through the assessment are already projected to generate over $2.5 million in recurring annual earnings (EBIT). Extrapolating the benefits across all identified opportunities reveals a total potential of approximately $15 million.

- Capability Building and Knowledge Transfer: A key success factor was the focus on knowledge transfer, moving the company towards complete self-sufficiency. The organisation has now developed its own custom tool based on the IfM methodology, empowering them to run the process independently. The “workout” events themselves have been a powerful team-building exercise, building automation capability and confidence across the organisation.

- Enhanced Decision Making: The tool has bridged the knowledge gap between technical teams and senior leadership. It provides a shared, robust decision-making platform for the company’s automation strategy, and is now embedded to a point where any major automation project must be validated through workout before it progresses.

The ultimate proof of the knowledge transfer is that the journey does not end with the initial engagement. The company now has a clear, independent vision for how the tool will support its long term automation strategy. The plan is to expand the programme to more facilities and empower sites to periodically reassess themselves every few years, recognising that as their capabilities evolve, new automation opportunities will emerge.

By partnering with IfM Engage, the company has not only built a multimillion dollar project pipeline but has also developed the internal capability and strategic clarity to sustain its automation journey for the long term.

On-demand Wabtec webinar: From Automation Ambition to $15M Impact

How do you turn 250+ raw ideas into a prioritised $15 million roadmap? Explore the full story of Wabtec’s data-driven transformation and discover how they secured leadership buy-in and built internal capability. Choose your preferred format below to dive deeper.

Insights for Your Automation Journey

For organisations considering using the IfM’s Automation Assessment Tool in scaling automation, Thomas Rupp, the project lead within Wabtec Corporation, offers this advice:

- Embrace Honesty: Be candid about your current capabilities. The tool is most effective when it is grounded in a realistic understanding of your starting point.

- Focus on the “Event”: The value extends beyond the tool itself. The collaborative “workout” process is a powerful mechanism for team building, creating consensus, and clarifying shared objectives.

- Invest in Dedicated Resources: A key insight was that successful automation implementation requires dedicated support at the site level. Proactively plan for a full-time automation resource to drive projects forward.

“The IfM Engage team were great partners in this project. Their expert facilitation of ‘workout’ events were key to securing buy-in from day one. They provided critical support for our pilot workshops and have been a fantastic source of guidance in helping us build the internal capability to scale the solution ourselves.”

Thomas Rupp, Lead Manufacturing Engineer, Wabtec Corporation

About Wabtec Corporation

Wabtec is a leading global provider of equipment, systems, digital solutions, and value-added services for the freight and transit rail sectors. With more than 150 years of experience, the company continues to set the standard in safety, efficiency, reliability, innovation, and productivity. From freight and transit to mining, industrial, and marine applications, Wabtec’s technologies and expertise are helping accelerate the future of transportation. At the core of its success are its people—the 27,000 employees across more than 50 countries whose collective talent, vision, and experience drive progress every day.

PROGRESS YOUR AUTOMATION JOURNEY

IfM Engage provides a structured and robust way to consider how automation could help your organisation, highlighting appropriate steps you need to take to progress along an automation maturity path.