Sustainable Manufacturing Course:

Cambridge’s Sustain 8 Open Programme

12-month Blended Learning Open Programmes from the University of Cambridge’s

Institute for Manufacturing with in-person and online components.

Who is the programme for?

Course tutors

More information

Who is the programme for?

Course tutors

More information

Sustain 8 Open Programmes are designed either for individuals or teams working to implement sustainable practices in a factory setting. They can turn sustainability strategy into daily action—delivering measurable improvements where they matter most: on the factory floor.

Over 35 factories across the world are using the University of Cambridge Sustain 8 methodology to deliver outstanding results. Join a Sustain 8 Open Programme to see how this approach can transform your organisation’s sustainability imperative.

Proven results

Factories using Sustain 8 regularly deliver:

- 20–30% improvement in electricity, water, material use, and waste.

- Significant performance improvements come from change generated by many small projects.

- Sustainable culture change across all levels of the workforce.

With no capex required to make these savings!

Achieve significant improvements across energy, material, and waste in just 12 months

WHY SUSTAIN 8?

Manufacturers today face significant challenges: rising costs and uncertain markets, increasing legislation and environmental/social regulation, growing customer expectations and demands on suppliers, scrutiny from NGOs and the media, and ongoing staff recruitment and retention issues. With numerous measurement and high Capex offered as the only solutions, sustainability is often seen as a costly extra problem.

At the same time many sustainability strategies get stuck at the analysis or asset investment stages. Sustainability professionals can become frustrated with progress when they don’t get support and traction from the workforce.

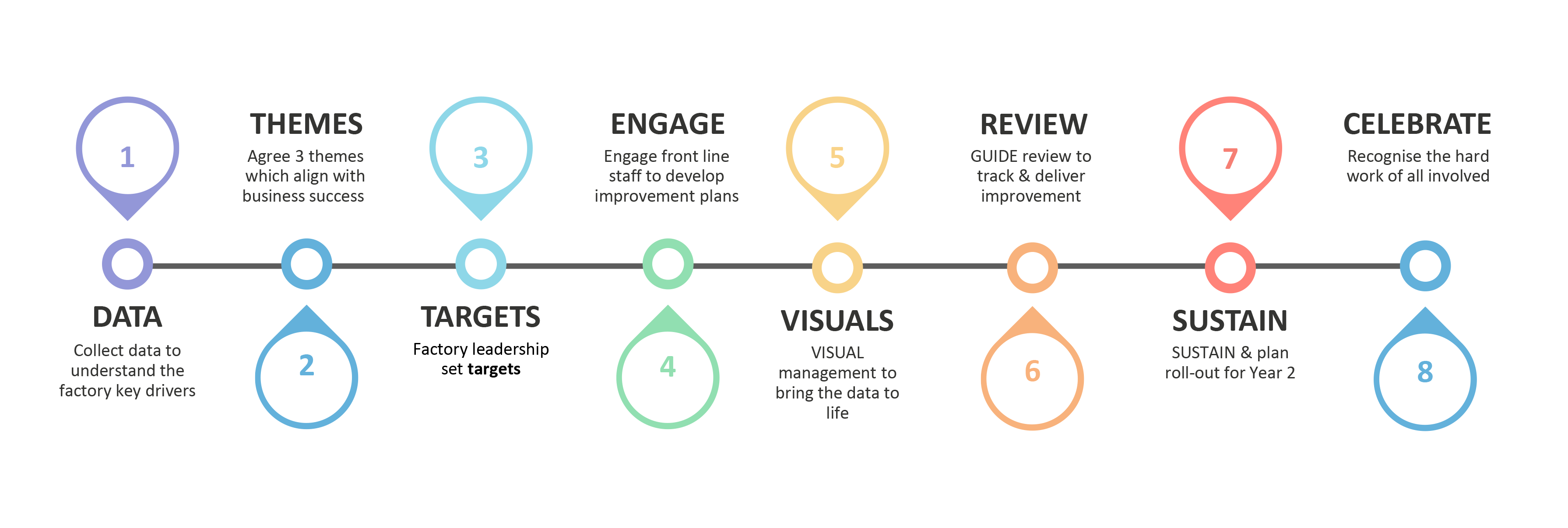

The Sustain 8 approach offers an alternative solution. It is a clear, simple sustainability and cost reduction methodology that solves many of these challenges. By focusing on engaging the entire factory workforce, Sustain 8 drives small improvements on a constant basis, leading to a continuous improvement staircase and embedding change within the culture. Unlike sporadic investment based activities, this approach is embedded in general factory improvement and becomes part of the way of doing business.

Continuous sustainable improvement, not one-off projects.

Real examples*

Biorefining: Energy +20%, Electricity +15%

Fashion: Energy +16%, Waste >30%

Footwear: Material >30%, Rework >30%

Metals: Packaging >30%,Waste +26%

*These results have been achieved through IfM Engage consultant-led programmes, in which an IfM Engage Industrial Associate delivers the Sustain 8 approach on behalf of the organisation.

Shop floor workers now own the energy-saving culture. Some team members have now moved to other factories and are implementing these ideas in these factories. So, the ideas and what we have learnt are spreading.

UPCOMING COURSES

Entry Requirements – check the criteria to make sure you are eligable for the programme.

Register interest or suggest additional dates – be notified when new dates are announced, or tell us what would be the best date range for you

Achieve significant improvement across energy, material, and waste in just 12 months

Sustain 8 Open Programmes are designed either for individuals or teams working to implement sustainable practices in a factory setting. They can turn sustainability strategy into daily action—delivering measurable improvements where they matter most: on the factory floor.

Over 35 factories across the world are using the University of Cambridge Sustain 8 methodology to deliver outstanding results. Join a Sustain 8 Open Programme to see how this approach can transform your organisation’s sustainability imperative with others facing similar challenges.

WHY SUSTAIN 8?

Manufacturers today face significant challenges: rising costs and uncertain markets, increasing legislation and environmental/social regulation, growing customer expectations and demands on suppliers, scrutiny from NGOs and the media, and ongoing staff recruitment and retention issues. With numerous measurement and Capex solutions available, sustainability is often seen as a costly extra problem.

Many sustainability strategies get stuck at the analysis or asset investment stages, failing to drive real action. Sustainability professionals can become frustrated when they don’t get traction on the shop floor.

The Sustain 8 approach offers a powerful solution. It is a clear and simple sustainability and cost reduction methodology that solves many of these challenges. By focusing on engaging the entire factory workforce, Sustain 8 drives small improvements on a constant basis, leading to a continuous improvement staircase and embedding change within the culture. Unlike sporadic activities, this approach is embedded and becomes part of the way of doing business.

Continuous sustainable improvement, not one-off projects.

Real examples*

Biorefining: Energy +20%, Electricity +15%

Fashion: Energy +16%, Waste >30%

Footwear: Material >30%, Rework >30%

Metals: Packaging >30%,Waste +26%

*These results have been achieved through IfM Engage consultant-led programmes, in which an IfM Engage Industrial Associate delivers the Sustain 8 approach on behalf of the organisation.

Proven results

Factories using Sustain 8 regularly deliver:

- 20–30% improvement in electricity, water, material use, and waste.

- Significant performance improvements come from change generated by many small projects.

- Sustainable culture change across all levels of the workforce.

With no capex required to make these savings!

UPCOMING COURSES

Entry Requirements – check the criteria to make sure you are eligable for the programme.

Register interest or suggest additional dates – be notified when new dates are announced, or tell us what would be the best date range for you

WHO IS THE PROGRAMME FOR?

The 12-month Sustain 8 Open Programme is designed for Implementation Leaders and Factory Delivery Teams working to self-deploy improved sustainable practices within their factories and are ready to lead an internal continuous improvement programme.

Implementation or Factory Leaders in Manufacturing

Ideal for individuals who are leading or shaping sustainability strategies and for factory teams—ideally in groups of three—comprising key front-line roles with the skills needed to drive a factory-wide programme:

- Sustainability or Environmental Professionals, Managers and Directors responsible for creating and implementing a company’s sustainability strategy, ensuring alignment with environmental regulations.

- Sustainability Specialists, such as energy specialists, waste management specialists or any other role focusing on environmental protection and resource efficiency, ready to lead an in-company training programme.

- Production and/or technical managers

- Continuous improvement champions

WHAT YOU WILL LEARN:

3 Skills Journeys

Participants will develop skills in the following areas:

Sustainability skills

Data Skills

Transferable skills

- Set and achieve sustainability targets using the Sustain8 method

- Energy and water efficiency optimisation

- Waste reduction and management

- Data collection to understand factory key drivers and areas of improvement in order to set targets and KPIs

- Data analysis and review process

- Data presentation, visual management and reporting

- People management skills using effective communication, building collaboration and trust

- Coaching and mentoring skills to support team members’ and to deliver results through factory teams

- Presentation skills to convey clear goals, expectations and giving feedback while active listening to team members to ensure alignment

THE LEARNING JOURNEY

The Sustain 8 Open Programme has two main components:

2-day in-person course to acquire the Sustain 8 method and be ready to self-deploy tools aimed at reducing energy and water consumption, minimising waste generation, and increasing rework efficiency.

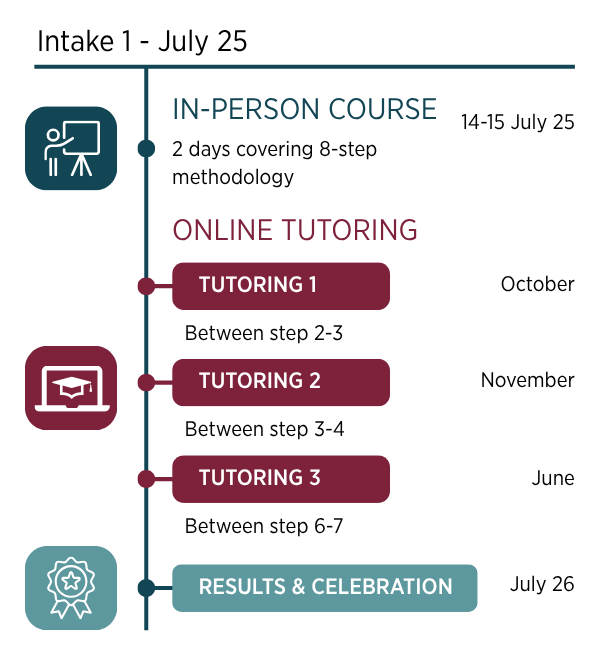

3 online, in depth, tutoring sessions to support the self-deployment of the method in your factory, engaging the workforce to implement the process. The tutoring sessions are strategically placed to align with the most crucial key points of the 8-step programme:

-

- Each participant will be trained to deliver improvements in one theme.

-

- Factory Teams who attend together would typically be encouraged to work together and to each choose a theme.

Sustain 8 Open Programme: 2 Intakes

WATCH THE WEBINAR

COURSE TUTORS

FIND OUT MORE AND ENROL

Ready to transform your factory’s sustainability performance, reduce costs, and empower your workforce?

Explore how the Sustain 8 Programmes could work for you. Contact us to schedule a call to discuss your interests.

MORE INFORMATION

Cambridge Sustain 8

Bespoke programmes

University of Cambridge endorsement

Booking confirmation and cancellation policy

Cambridge Sustain 8

Bespoke programmes

University of Cambridge endorsement

Booking confirmation and cancellation policy